Your Compounding Resource for

Specialty and Performance Polymers

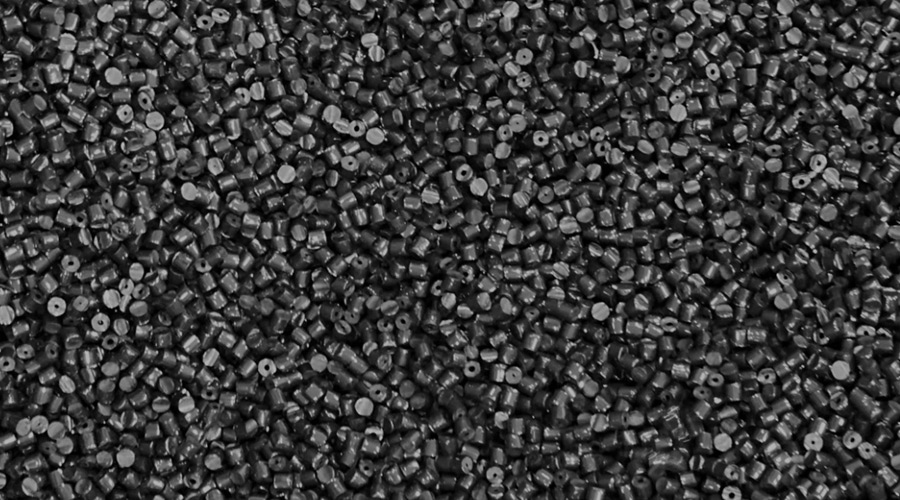

For nearly 20 years, Ovation Polymers has provided advanced, reliable custom and toll compounding for specialty polymers and performance polymers. Learn how we’ll take your product to the next level.

Our Specialty & Performance Polymers

Discover our full line of proprietary polymers and composites, including everything from electrically and thermally conductive compounds to high-performance masterbatches that serve as the foundation for your material formulation.

Quality Systems & Certificates

With an ISO 9001:2015 quality management certification, a 99% on-time delivery rate, and frequent auditing from external partners, rest assured that your materials and their performance will be second to none.

Our Commitment to Safety

Thanks to rigorous internal safety education and training, we have achieved significant milestones for no lost-time accidents. Learn about our safety commitment and how it protects our team.

Compounding Services

We offer toll compounding services to produce virtually any specialty polymers and performance polymers, as well as custom compounding to identify the right material formulation for your needs.